Mastering DTF Printing: A Comprehensive Overview to Direct-to-Film Techniques

Mastering DTF Printing: Tips and Techniques for Getting Vibrant and Long Lasting Prints

In the world of textile printing, attaining resilient and dynamic prints is a desired ability that can boost the high quality of your output. From picking the right materials to fine-tuning print setups and perfecting post-printing completing strategies, there are countless variables that can affect the end result of your prints.

DTF Printing Fundamentals

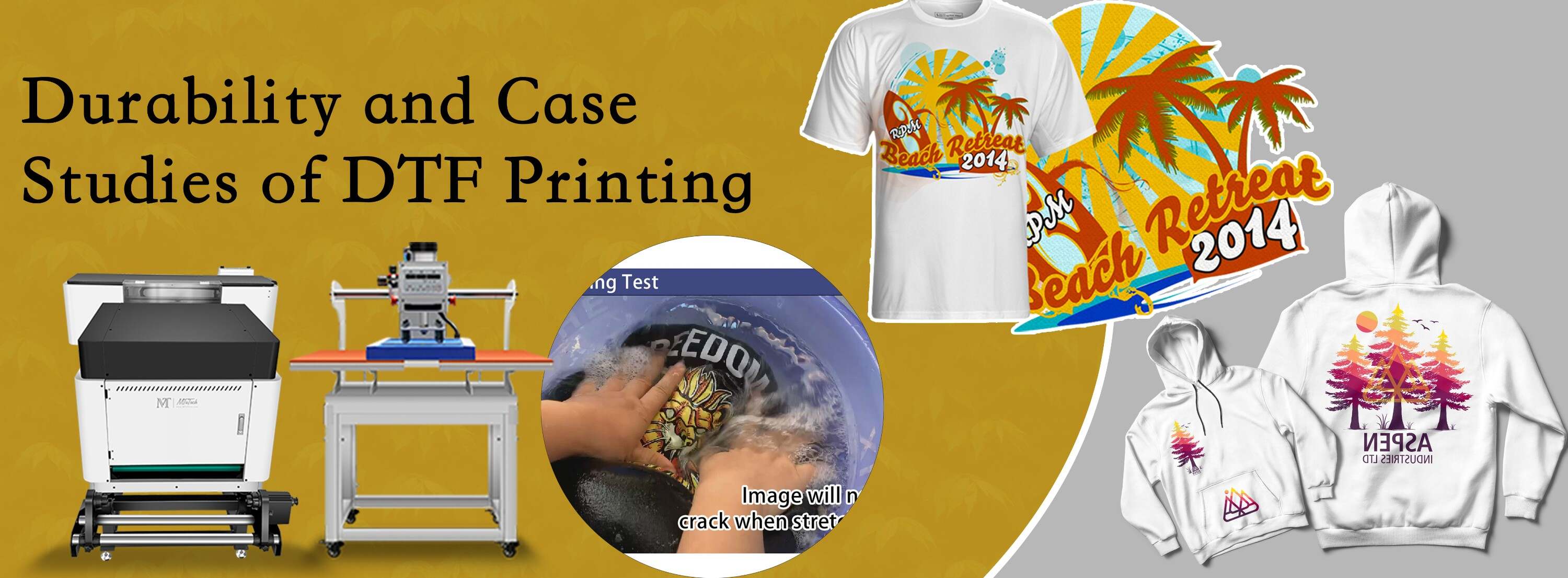

For those brand-new to the globe of textile printing, understanding the fundamentals of DTF printing is vital to mastering this cutting-edge method. Direct to Movie (DTF) printing is a modern-day technique that involves moving layouts from a special film onto different textiles using a warmth press. Unlike standard techniques like screen printing, DTF supplies advantages such as vibrant shades, intricate detailing, and the capacity to publish on diverse products like cotton, polyester, and blends.

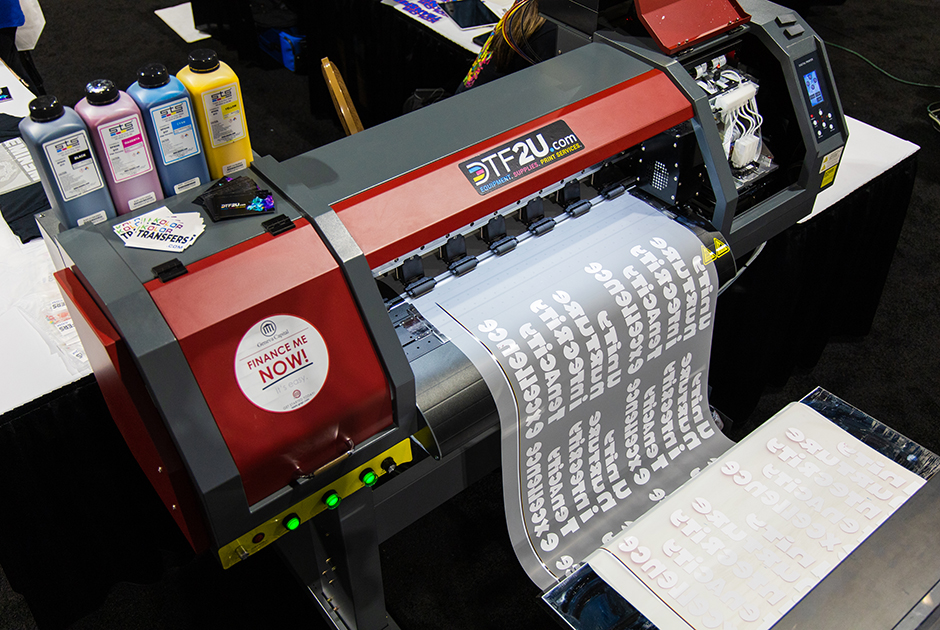

The process starts by publishing the style on a special DTF film making use of a compatible printer with CMYK or CMYKW ink collections. When the design is published, it is then healed with a warmth press to produce a resilient and durable print. DTF printing is recognized for its ability to duplicate complicated designs with high accuracy and shade precision, making it a popular choice for companies wanting to develop custom-made apparel, promotional products, and more.

Selecting the Right Products

Similarly essential is the choice of the sticky powder. The adhesive powder works as a bonding representative in between the published design and the fabric, so it should have solid attachment homes to ensure a long lasting and durable transfer. Various textiles may call for various kinds of adhesive powders, so it is important to match the powder to the material kind for optimal outcomes - DTF Printing. By carefully picking the ideal products for DTF printing, printers can enhance the quality, vibrancy, and longevity of their prints.

Maximizing Print Setups

When intending to achieve the finest outcomes in DTF printing, precise focus to enhancing print settings is essential for guaranteeing exact and high-grade transfers onto textiles. One crucial facet to think about when maximizing print setups is the resolution.

While raising the rate can enhance efficiency, it may compromise the final print's quality and shade saturation. Experimenting with different speeds and observing the results can help identify the ideal setup for each print job.

Moreover, tweak shade profiles and making certain proper shade administration are important for attaining precise and constant shades across different prints. By calibrating shade setups and accounts, printers can minimize color deviations and produce uniform results, boosting the total print top quality and consumer fulfillment.

Preparing Artwork for DTF Printing

To ensure optimal results in DTF printing, precise interest to detail is necessary when preparing her latest blog art work for transfer onto textiles. Begin by selecting high-resolution pictures to preserve quality and sharpness in the last print. Vector graphics are liked as they can be conveniently scaled without losing high quality. Transform the art work to CMYK shade setting to make certain that the colors translate accurately from screen to print. Readjust the shade levels and contrast as required to boost the vibrancy of the design. When including text to the art work, select fonts that are legible and appropriate for the intended size. Keep in mind to mirror the final style before printing to ensure that it moves properly onto the garment. In addition, take into consideration the fabric type and color when picking the art work, as these aspects can influence the last look. By complying Homepage with these actions and paying very close attention to the details, you can prepare artwork that is optimized for lively and long lasting DTF prints.

Post-Printing Finishing Methods

Carrying out reliable post-printing completing methods is important to enhancing the resilience and aesthetic charm of DTF prints on fabrics. When the printing procedure is full, using heat to the published design is essential.

When the film is removed, the print may require extra treating time to further set the ink right into the textile. This action assists boost the washability and durability of the print, ensuring it can stand up to several clean cycles without fading or splitting.

Additionally, trimming any excess film around the style can offer the last print a professional and clean look. Making the effort to effectively end up DTF prints post-printing can substantially affect the overall quality and longevity of the textile design.

Verdict

To conclude, mastering DTF printing calls for a complete understanding of the essentials, choosing proper products, optimizing print settings, preparing art work effectively, and utilizing post-printing ending up strategies. By complying with these suggestions and techniques, one can attain durable and vivid prints that satisfy their desired quality standards. Regular method and focus to information are essential in attaining successful results in DTF printing.

From picking the best materials to fine-tuning print settings and improving post-printing completing techniques, there are countless variables that can influence the end result of your prints. Unlike typical approaches like screen printing, DTF supplies benefits such as lively shades, intricate detailing, and the capacity to publish on varied products like cotton, polyester, and blends.

Once the layout is printed, it is after that healed with a warmth press to create a resilient check over here and durable print.When aiming to accomplish the finest results in DTF printing, precise focus to optimizing print settings is essential for making sure exact and high-quality transfers onto fabrics.In final thought, mastering DTF printing needs a comprehensive understanding of the basics, selecting suitable materials, maximizing print settings, preparing art work successfully, and making use of post-printing completing strategies.